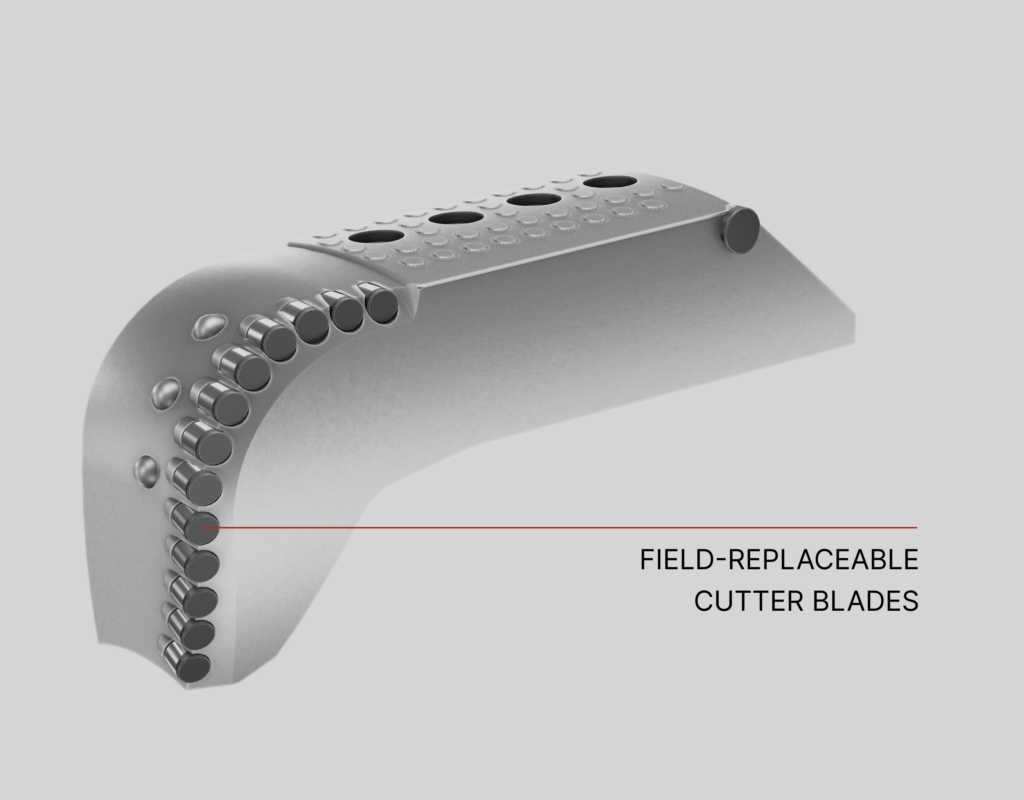

Field-replaceable cutter blades

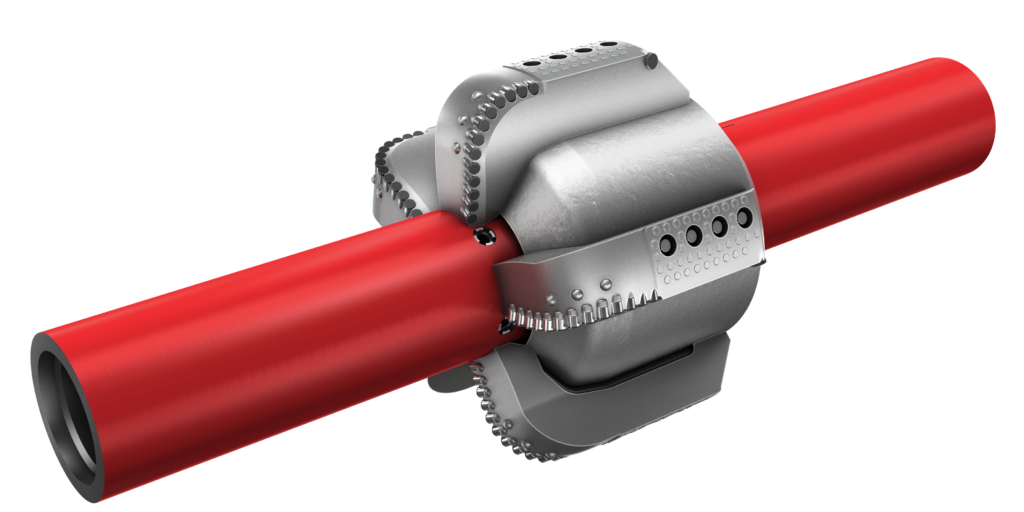

The PDC Reamer has curved cutter blades for smoother, more stable drilling with minimal vibrations. The cutter blades are easily changed in the field, avoiding shipping back and forth to the workshop for blade replacement — a good investment for your productivity and the environment.