The value of annular pressure monitoring

Published — 2021-12-08As the world continues to focus on sustainable business practices, the scrutiny of infrastructure projects has increased across the board. Doing all we can as an industry to mitigate environmental impact is critical, particularly issues such as inadvertent returns (“IR”). It is not possible to fully eliminate the risk of IR events, but there is Horizontal Directional Drilling (HDD) technology that can help mitigate it.

What tools are available?

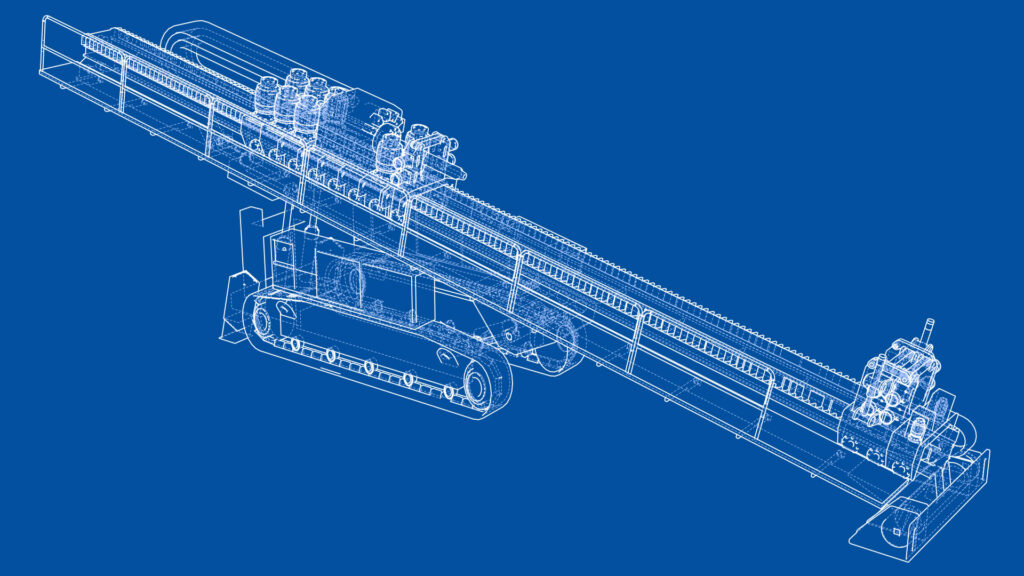

There are reliable and proven downhole tools that are able to monitor annular and drill pipe pressure in real-time. Pressure tools are typically deployed as an addition to the wireline steering system, for use during the pilot hole drilling, but they can also be used as standalone tools for reaming applications. The data from the pressure tool can then be fed to an EDR (Electronic Data Recorder) system to record and share pressure data and other drilling parameters with project stakeholders in real time.

Tooling only part of the equation

Leveraging pressure tools and EDRs to monitor pressure levels is only part of the solution to manage IR risk. HDD engineers and project owners need to perform a geotechnical analysis and integrate those results into a hydrofracture analysis to properly assess IR risk. These results then need to be incorporated into bore design and project/contractor drilling requirements.

So why run pressure tools?

Monitoring pressure levels can be helpful to mitigate IR risk as a standalone measure. Monitoring annular pressure allows drillers, engineering firms and inspectors to recognize potentially dangerous trends and take precautionary actions such as cleaning the hole or adjusting the fluid program before an undesirable event occurs. It provides a record of pressure levels and other drilling parameters which can be used to demonstrate compliance with project specifications and better understand drilling operations. In addition, the cost of delivering this solution is low in absolute terms, and practically irrelevant in the context of an IR. INROCK has a significant experience running pressure tools, having operated them on thousands of jobs worldwide as a part of our guidance service offering. In addition, INROCK has trained customers to run pressure tools themselves. Call INROCK today to learn more about these solutions!